METALLIZZAZIONE - VERNICIATURA - STAMPAGGIO

VAQUARZ opera da oltre 30 anni nel mercato degli apparecchi di illuminazione ad alto rendimento. In pochi anni, si è imposta come azienda leader nel settore, riuscendo a fare dei suoi impianti e della professionalità del suo personale i punti cardine del proprio successo. Ancora oggi è la più importante realtà per la metallizzazione in alto vuoto ed il trattamento delle superfici riflettenti in genere che realizza con uno dei più moderni impianti esistenti sul mercato.

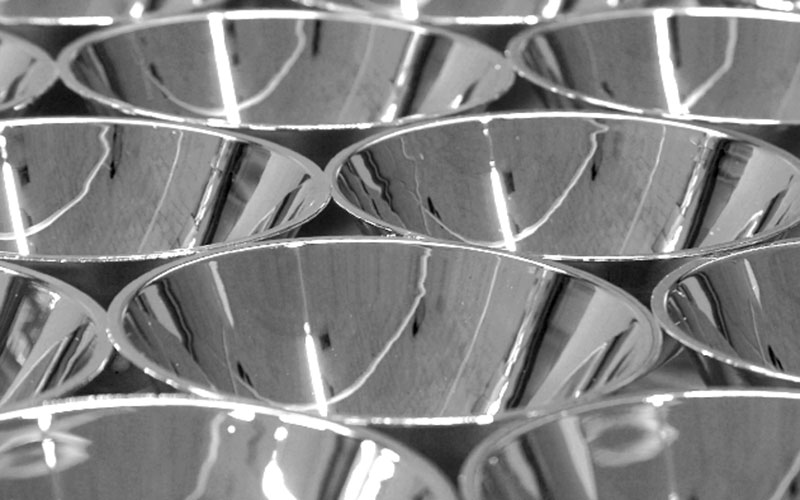

In particolare ci occupiamo di metallizzazione in alto vuoto di riflettori per illuminazione.

È necessario un costante rinnovamento ed una rivisitazione periodica di prodotti e dei servizi, nonché dei nostri processi, per tenersi aggiornati su ciò che il mercato richiede e sulle nuove tecnologie. Per maturare tutto questo la competenza professionale del personale richiede un costante impegno nella ricerca e nello studio di metodologie innovative ed al passo con i tempi.

VAQUARZ fornisce servizi altamente qualificati in ogni sua specializzazione ed è capace di misurare tempi e modalità per la migliore concretizzazione del servizio richiesto.

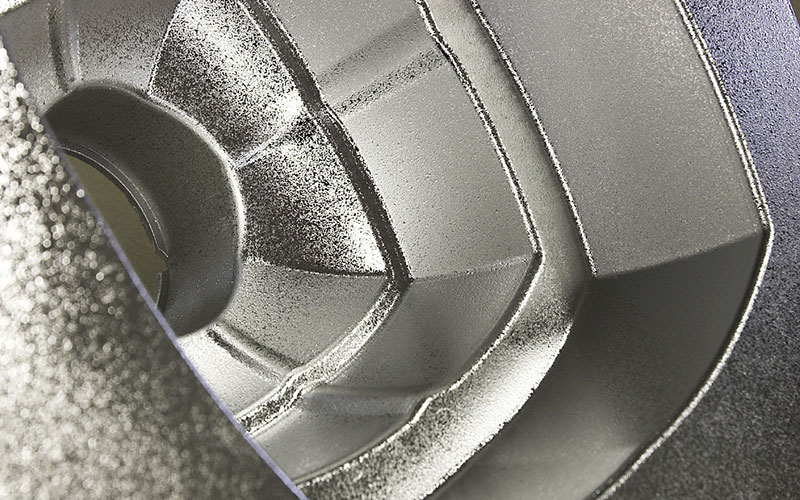

- metallizzazione in alto vuoto cioè deposizione di strati sottili, multipli (metallici e non metallici) su superfici di plastica, vetro, metallo e ceramica mediante la tecnologia dell'evaporazione in alto vuoto

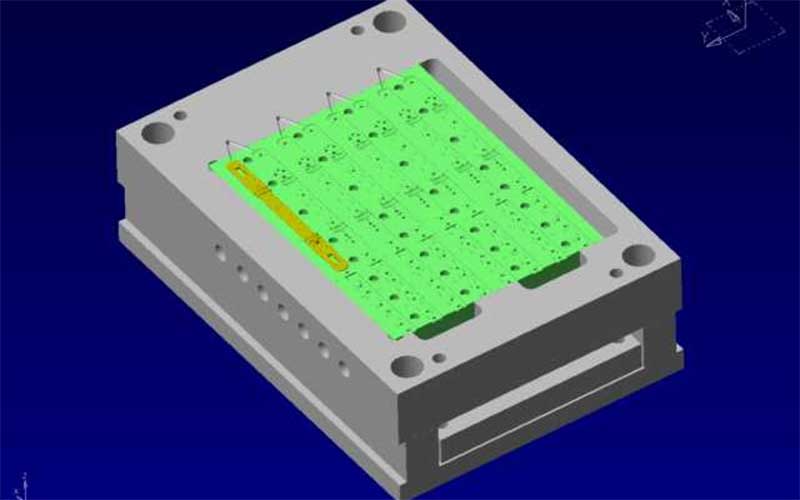

- progettazione computerizzata e realizzazione di superfici riflettenti

- stampaggio di prodotti termoplastici e metallici (anche su progetto del cliente) e costruzione di stampi

- costruzione e la fornitura di complessi ottici ed elettronici assemblati, preassemblati con portalampada o vetro di sicurezza

- lavorazioni con presse per imbutitura di supporti riflettenti (alluminio, ferro, ottone)

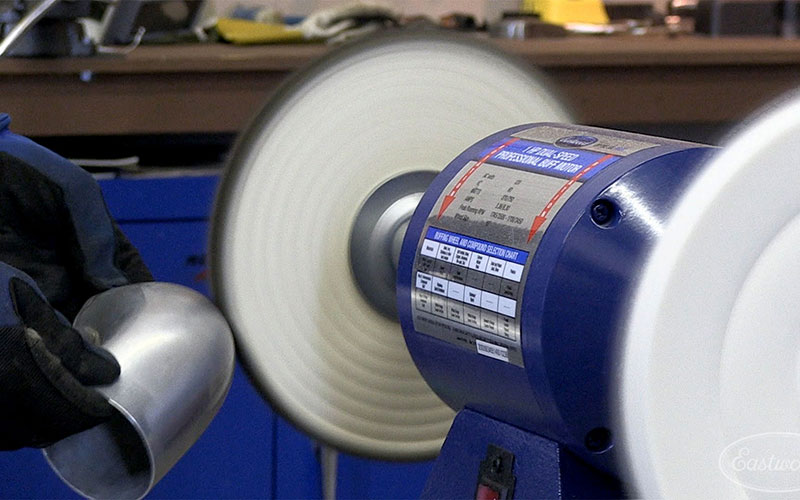

- verniciature pre e post metallizzazione o con protezione del riporto per mezzo di successivi riporti chimici

- protezione dei metalli mediante strati anticorrosione

- verniciatura su qualsiasi materiale a cariche elettrostatiche ed a polveri epossidiche.

Scopri la nuova gamma di riflettori per LED.

I nuovi riflettori possono essere completati con un pratico holder in materiale termoplastico da applicare sopra alla sorgente luminosa. L'holder fornisce un comodo attacco a baionetta che permette di fissare il riflettore senza usare viti o altri sistemi.